Product Design

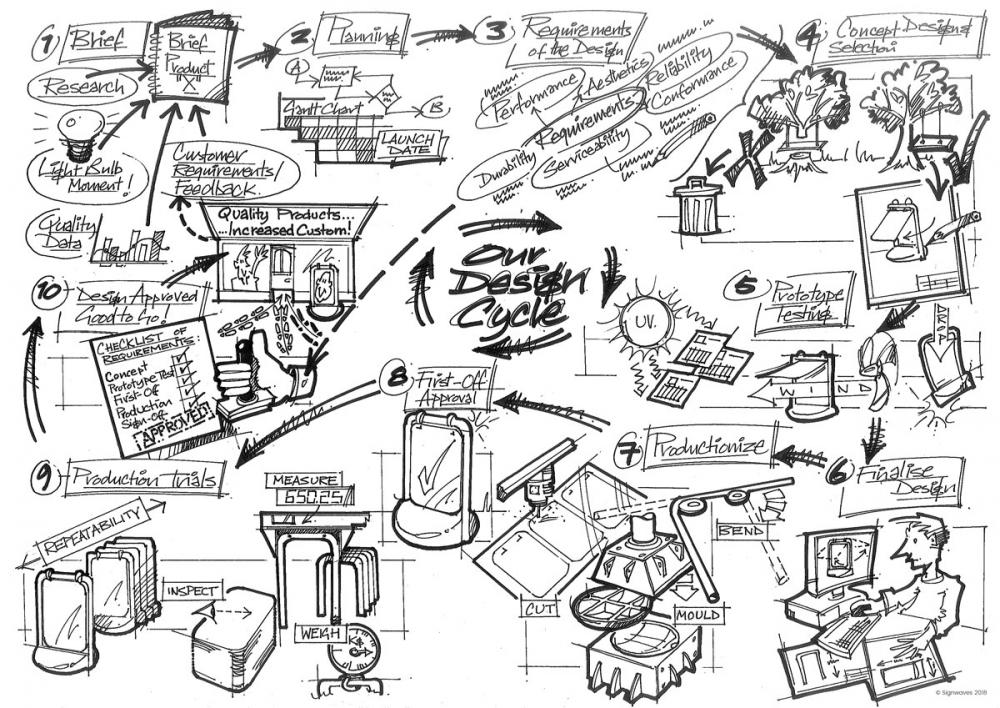

Developing successful products repeatedly is how we demonstrate the strength of the creative process within the business. Within our culture it highlights three core elements – the ideas, the team and the approach.

With an extensive portfolio of patents and registered designs, and awards to their name, our D&D (Design and Development) team have every right to be proud of their legacy - and contribution to Signwaves success. It is a legacy built on years of experience, market knowledge and continuous improvement.

Customers and new staff sometimes ask why it takes so long to bring a new product to market. A response might be that ‘making things is easy, making things better that are well designed, functional and value for money is not.’ We do not cut corners, and whilst this means we may take a little longer to finish a project it will not result in us supplying mass produced prototypes!

Time is needed for research, investigation, obtaining customer and supplier input, concept sketching, CAD, 3D modelling, engineering, testing, packaging design, costing, checking and final verification. Our team of designers, engineers and technicians have to be curiosity driven problem solvers – and decent project managers too!

Probably the most effective form of sustainability is a product that performs well and lasts longer. A product might appear the most sustainable in terms of material choice, but if it requires replacing prematurely it and we will have failed.

Get in Touch Today

Contact our team today to discuss your project, request a quote, or learn more about

how Signwaves can support your display and signage needs from concept to completion.